Servicios al cliente

Sobre nosotros

Copyright © 2024 Desertcart Holdings Limited

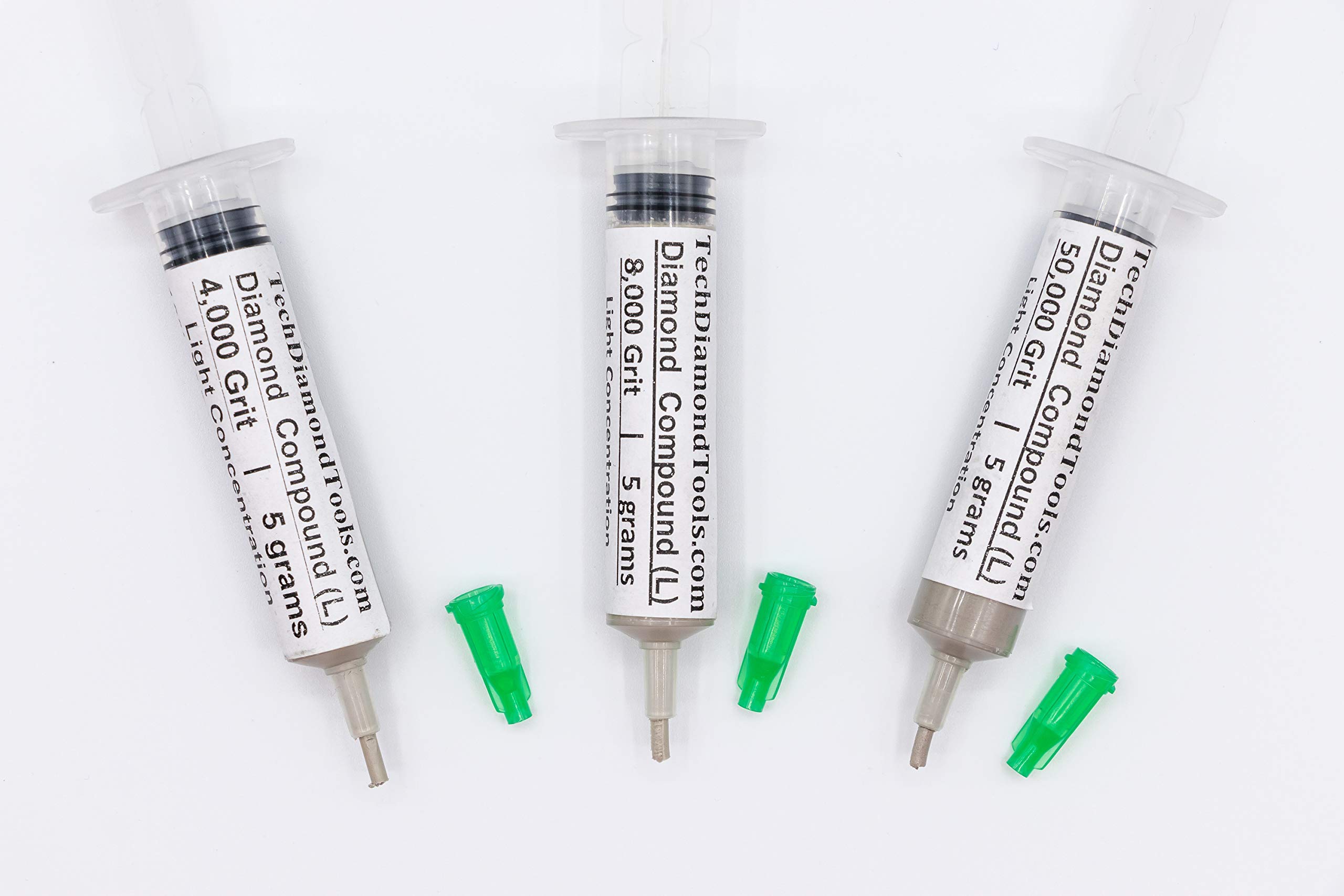

✨ Elevate Your Shine Game with TechDiamondTools! ✨

The TechDiamondTools Kit includes three diamond polishing compounds (4000, 8000, and 50000 grit) made in the USA, featuring a 10% concentration of diamond powder. This industrial-grade, oil-based formula is designed for precision polishing across various materials, ensuring a flawless finish for professionals and hobbyists alike.

J**A

Works to get that final sheen.

I’m a general contractor and remodel kitchens and baths. I install tops in house and use polishing discs and powders. I purchased this with no expectations since the amounts in those tubes didn’t look like very much. I was working on a quartzite seam and got it 90% of the same sheen as the existing top using discs and a polishing paste brick. Then I used this to get it the rest of the way. I put just a small dab on a gloss polishing pad. That little dab was enough to do 1/2 the length of the seam, another dab did the rest. I didn’t use the lower grits, I started with the highest since I was close to the matching sheen. I would recommend this for any situation where you need just the top layer buffed to a sheen.

B**Y

Worked great, just as expected

This buffing compound has worked exceptionally well. I have used it twice so far and it performed just as expected.My first use was on a bathroom faucet. There was some sloppy casting and finishing work on a small section of the faucet that my wife just finallly got tired of looking at. She wanted to replace it. Instead, I started with the 1,050 grit and a dremel with buffing attachment to make quick work of cleaning up the physical blemishes and matching the rest of the area. I moved to 1,500 grit with the tool and a new attachment to refine the finish. Then I used the 3,000 grit and a new attachment to take it to the final finish. Lastly, I used a rag, finger and the 3,000 grit to remove the pattern left by the tool and make everything uniform. It looks great, my wife is pleased and I don’t have to replace the fixture I installed not all that long ago.I also used it to clean up the scratched resin “crystal” of my work watch. All the beatings had left the watch “crystal” scratched and it was difficult to see the small digital display at the bottom of the analog watch face. Using a rag I started with the 1,050 grit and worked my way to the 3,000 grit. The “crystal” is once again shiny and I can see the digital display perfectly well. I didn’t get rid of the deepest gouges but I’m unconcerned as my goal was just to be able to see the display. It took me, maybe, a total of 15 minutes between getting everything out, buffing and rinsing. If I had been more concerned with trying to get rid of more scratches it may have been possible by spending more time but the goal was accomplished.

D**.

Great on glass

Great price and works well on glass

D**D

A subtle difference

The polish did help but I probably should have chosen a rougher polish since the scratches are deeper than I thought.

A**X

Didn't completely remove deep scratches but plenty good enough.

I had 4 deep scratches (I could catch a fingernail on them) right in the middle of my Garmin watch. After 20 mins with a Dremel and the 2000 then 4000 then 8000 grit the 4 scratches are still there but only visible if it catches the light just in the right way. And when it does I can't read the watch anyway because of the glare. Prior to the polishing the scratches made terrible shadows across the watchface. This photo is in full afternoon sun.There are still 2 small scratches that I haven't worked at very much and I'll probably leave those as they aren't very noticeable.I think you could do this by hand but it would take a very long time. If you are trying to fully remove a deep scratch you should probably go down to a lower grit.

C**S

Got deep scratch out of mineral crystal

I had a deep scratch in my mineral crystal, deep enough to cast a shadow on the dial of my watch. It's an inexpensive enough watch that I figured I'd risk trying to get it out rather than sending it for glass replacement.The 3000,5000,14000 grit worked perfectly. I used a dremel tool with the polishing wheel and worked up to the high grit, applying moderate pressure in small circular patterns. DO NOT TAPE YOUR DIAL TO SECTION OFF THE SCRATCH. I did that initially and it caused a "step" from where the tape ended and the compound was contacting the glass. Instead, keep the entire face of the watch uncovered and apply pressure localized at the blemish and fan out applying less pressure as you get further away. With this method I was able to get rid of the scratch and step caused be the lower grit with tape. It took about 30 minutes in total, initially it seems like it wasn't going to work but if you keep at it, it works great. I don't know how well ot would work applying by hand, but with the dremel this was a breeze.

D**L

I love this stuff.

I collect\repair watches and I do some gunsmith stuff and now am making some knives from kits. some watches old and new come with a hard glass crystal which is really ugly when scratched. Nothing else will touch those scratches. Also for a fine mirror like polish on stainless steel like guns or knives? This is the stuff. For most people I would say the 1200/2000/4000 is a good selection to have. They make 40-50 thousand also. One thing to note is that the grit sizes on these diamond pastes is not the same as say 2000 grit sandpaper or 1200 grit stones. this is perhaps milder... I have some paste in 400 grit that is great to start out with on deep scratches. it is not like 400 grit sandpaper tho. More like 1000 grit sandpaper? This is a good thing tho since it is hard to really harm something with this paste. anyway.. good to have around and easy to use. 5 grams does not seem like a lot but believe me.. it is used sparingly. A couple of finish nail dollops each time and then rub rub rub.

R**O

Sin instrucciones

sin instrucciones para el uso. Dificil

Trustpilot

Hace 1 semana

Hace 2 meses